UPGRADING YOUR OPERATIONAL ENGINE

Are your organizational structures of people, information and process outdated?

At a recent OESA event, speaker Jim Collins (author of Good to Great) stressed the importance of the who over what when preparing for disruption in the automotive supply industry. There is growing uncertainty from economic conditions, changes to the OEM product mix and new technology. Keeping up to date with the disruption, along with the challenges in day-to-day operations, is overwhelming. Having the right people in place will ease the burden, but only if they are enabled to work together to tackle your pain points and profit from gaps in the market. The organizational engine currently in use may not be agile enough to adjust and grow with the dynamic market. Rethinking how teams work together will be required to stay competitive.

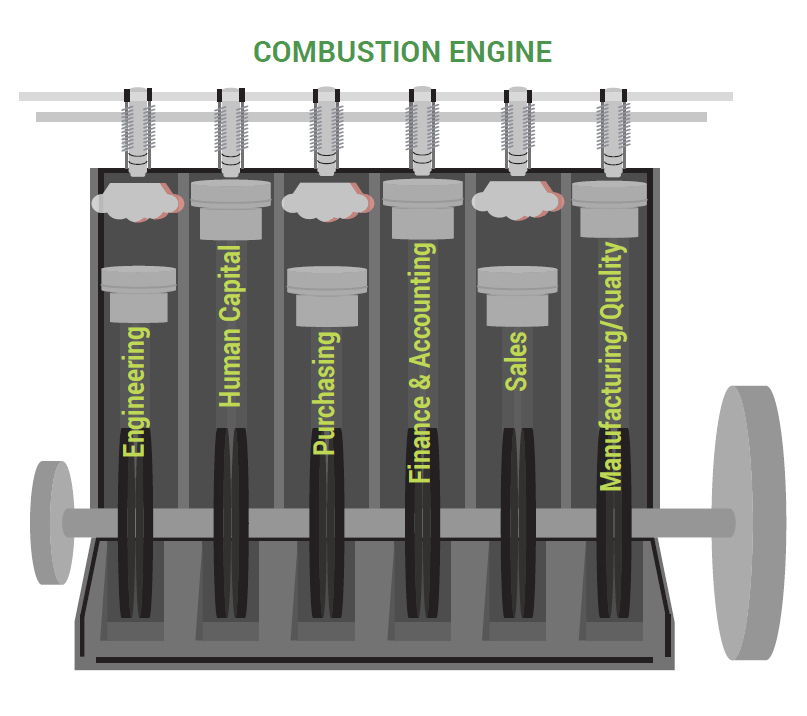

How manufacturing organizations operate today can be compared to a well-tuned combustion engine. Each functional area acts like a separate piston that fires, driving the organization forward. Management oversees the timing and improvement of each functional area by considering the mix of resources needed to ensure constant power is being delivered. OEMs place constant pressure on suppliers to reduce costs while improving output. As a result, management tasks each functional area to reduce costs while meeting higher internal KPI targets. Advances made in such silos may enhance the performance of one function at a different pace than others, causing an imbalance and reducing overall performance. An example would be if sales won a large program order, but finance is unable to predict the costs accurately, or production is unable to meet delivery. The contract would actually have an overall negative effect on the organization. Each “piston” becomes optimized, but if they do not communicate with each other, then the engine stalls. When an organization requires manual pushes of information, constant corrections are needed. A well-tuned organizational engine can only operate at peak performance when experienced talent knows how to make micro adjustments. But talent is difficult to retain as many begin to retire and newer employees lack experience.

Uncertainty in the marketplace will require frequent updates to your plan. When purchasing shifts suppliers due to tariffs, it impacts the timing of production. As the global economy moves, the businesses’ financial organization may need to make changes to cash flow. New regulations require different amounts of information to be collected, stored and reported. If the functional areas in your organization are always tied up communicating updates to their unique plans to the other functional areas, there will be far less time available for execution. A key priority for long term success is making sure that the updates to the master plan and communications thereof are as frictionless and as easy as possible.

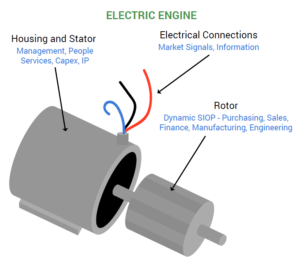

Shifting to an Electric Vehicle (EV) Operational Engine

The structure of manufacturing companies in the future may look a bit more like an electric motor. Electric power flows from the stator into the rotor that drives the shaft forward. The stator is stationary no matter how fast the rotor spins and can speed it up or slow it down. The stator represents management, people services (talent), capital expenditures (plant and machinery) and engineering (IP) that hold constant in the long run. The rotor core represents how materials flow through the organization in the short-term. Sales Inventory Operations Planning (SIOP) and manufacturing need to rapidly change based on the market conditions. The electricity in an electric motor is constantly flowing, much like data information constantly flows through a business, where updates to one function change the plan of others with as little friction as possible. Fewer parts in EV motors increases the simplicity of changing the speed, much like fewer connected information software in business operations become more agile.

Across the entire automotive value chain, whether you’re an OEM, Tier 1, 2, or 3, leadership needs to think about how these macro-level shifts will impact their organization. Automotive manufacturing organizations are creating new operating models to mitigate risk from industry and global uncertainty. By being proactive and developing a new mindset and customer-centric culture grounded on how information continually changes and flows across functions, companies can better prepare for the disruption ahead. As the industry continues to evolve and vehicle volume levels decrease, suppliers and OEMs will look for new revenue streams. These revenue streams will come from the monetization of both vehicle and end-consumer data collected throughout the production process and end-user experience. The automotive marketplace will continue to see an explosion of in-car technology and integration focused on data centralization in order to provide unique experiences and generate revenue. This requires developing a strategy for the future and taking stock of the present. By focusing on a hybrid system architecture today, companies can transition to a data-intensive future. To learn more about how information can be leveraged in your company, read our data-driven decisions e-book.

This post is a collaborative contribution authored by Peter Pearce.